Tungstalon is a Revolutionary Lightweight Product

Tungstalon is a revolutionary lightweight product that exceeds the versatility of carbon fiber. Carbon fiber-reinforced composite materials are used to make aircraft and spacecraft parts, racing car bodies, golf club shafts, bicycle frames, fishing rods, automobile springs, sailboat masts, and many other components where light weight and high strength are needed. Tungstalon is a true carbon fiber alternative at a better price point. Since carbon fiber is very scarce, and production cannot keep up with demand, Tungstalon can fill that void at a much better price point. Tungstalon is a blend of tungsten nanotubes and nylon. Tungstalon has the major advantage that it can be injection molded to create parts, where carbon fiber cannot. Tungstalon has higher temperature capabilities and stronger composite tinsel strength. For these reasons cogs, gears, and countless parts made from Tungstalon are far superior to plastic parts.

Tungstalon and tungsten fiber are revolutionary lightweight products

About Tungstalon

Tungstalon is a Mixture of Nylon and Tungsten nanoparticles. It can be manufactured into either fiber or pellets,

depending on the end user’s needs. To create Tungstalon we heat nylon to around 400 degrees where it becomes soupy and runny. Then we pour dry nano tungsten spheres into it and thoroughly mix it. The result is a black nylon liquid that can be formed into almost anything. We then run it through an extruder that pushes out a fishing line type thread. The thread is rolled on a spool. The spool of thread is sent to a company that has industrial weavers. The thread is then woven into a fabric. many applications and pellets for injection molding machines.

Versatility

Tungstalon is One of the Most Versatile Substances

Injection Molding

Tungstalon’s base materials can be extruded into fibers for use in molds with resin or injected into molds for durable parts.

Tungstalon Pellets

These pellets are sent to companies that do injection molding.

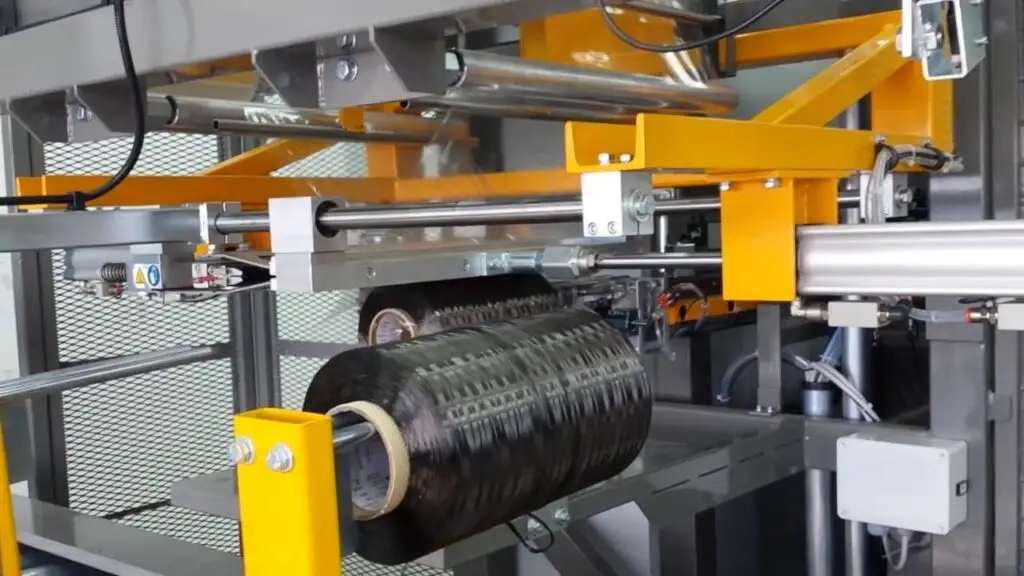

Extruder

We then run tungstalon through an extruder that pushes out a fishing line type thread.

Tungstalon Fabric

The fabric can then be made into anything that uses fabric, such as jackets, tarps, and cloths for example.

Tungstalon Parts

Tungstalon can be used in parts for countless industries. For example, the automotive, aerospace, tool, sports and toy industries.

Tungstalon Thread Spools

The spool of thread is sent to companies that have industrial weavers.

The Benefits of Tungstalon

Many Distinct Advantages

Tungstalon has numerous benefits, standing out from the crowd for several reasons. Below are just a few of the benefits of Tungstalon and why it will be the choice material of many engineers and designers around the world. Tungstalon is a low-density material with a very high strength to weight ratio. This means that carbon fiber is tough without getting bogged down like steel or aluminum, making it perfect for applications such as cars or airliners. Additionally, Tungstalon has superior fatigue properties compared to metal, meaning that materials made out ofTungstalon won’t wear out as quickly under the stress of constant use. Tungstalon is also known for its high-tensile strength thus making it suitable for many applications.

The advantages of Tungstalon are:

- Higher temperature capabilities.

- Increased Durability over typical plastic injected parts.

- Superior price point.

- Stronger composite tinsel strength.

- Unlike carbon fiber that is scarce and cannot keep up with demand, Tungstalon can be produced in abundance and can meet or exceed demand.

- Opens many opportunities for new markets.

Why Choose Tungstalon

Because of its impeccable strength-to-weight ratio, Tungstalon can be used across a number of fields and applications. It can also be shaped and molded in ways that traditional materials, such as aluminum and steel cannot. Unlike most metals, which tend to corrode when exposed to moisture and harsh chemicals, Tungstalon has exceptional corrosion and wear resistance. This makes Tungstalon well suited for environments where it might be exposed to salt water or corrosive chemical agents.

“Is Tungstalon waterproof?” is a question we’re regularly asked. And the answer is yes! Tungstalon is waterproof. Unlike many other materials, the Tungstalon forces moisture to the surface where it can evaporate. Because it doesn’t retain or absorb moisture, it’s less likely to grow mold or other fungi, saving you on cleaning costs and time. That’s why Tungstalon is ideal for products that need an element of waterproofing, like shower curtains and climbing equipment. The versatility and clear superiority of Tungstalon truly opens up a plethora of markets and applications.

TUNGSTALON

The Tungstalon formula combines Zytel FR15 is a flame-retardant PA 66 resin that meets the requirements of UL94V-0 at thicknesses down to 0.75mm (0.03in). Zytel FR15 does not contain phosphorous or halogens.

Tungstalon is a high-performance plastic formed from tungsten WS2 tungsten nanotube particles in an 80% NYLON to 20% tungsten nanotube particles formula.

The mixture is prepared by grinding the nylon into a fine grain powder, then blending the tungsten nanotube particles in an 80% nylon and 20% tungsten WS2 tungsten nanotube particles compound. The blended Tungstalon is then placed in a plastic extrusion machine. The Tungstalon compound melts and it is extruded into a .25mm cord which is then cut into pellets.

Tungstalon and Wind Turbine Blades

Tungstalon could bring cost and performance benefits to the wind industry if developed commercially, opening up yet another market. Research shows that Tungstalon performs better than current commercial materials used in making wind turbine blades in terms of cost-specific properties of most interest to the wind industry.

Wind blades containing Tungstalon weigh 25% less than ones made from traditional fiberglass materials. That means Tungstalon blades could be longer than fiberglass ones and, therefore, capture more energy in locations with low wind. A switch to Tungstalon also could extend blade lifetime because carbon fiber materials have a high fatigue resistance.

Tungstalon has performance characteristics that have higher value for the specific loads that a wind turbine experiences. Developing Tungstalon commercially can enable the benefits of Tungstalon materials to be realized more broadly by the wind industry and lower the overall cost of wind energy.

TUNGSTALON APPLICATIONS

Sporting goods:

Tennis rackets, golf clubs, softball bats, hockey sticks, and archery arrows and bows are all products that can be manufactured with Tungstalon. Lighter weight equipment without compromising strength is a distinct advantage in sports, and this is where Tungstalon shines.

Military:

The military was the first industry to use carbon fiber in a significant capacity. The military currently uses carbon fiber for rockets and aircraft components, among a host of other applications. This makes the military the perfect candidate for the vastly superior Tungstalon with its better price point.

Aerospace:

The aerospace industry was one of the first industries to adopt carbon fiber. Starting with Rolls Royce’s carbon fiber compressor blades in jet engine assemblies in the 1960s, the aerospace industry quickly began looking into carbon fiber as a replacement for aluminum and titanium in certain types of components. Much of this interest was due to the superior strength-to-weight ratio of carbon fiber compared to other metals. Because of Tungstalon’s superior properties and costs, the aerospace industry is a perfect match and a space that we can dominate.

Automobiles:

Tungstalon is poised to be adopted rapidly in automobile manufacturing. The material is ideal for use in Formula 1 and NASCAR vehicles due to its strength-to-weight ratio, which helps develop faster cars. The material should easily gain traction in the production of high-end cars due to its sleek, high-tech look. Tungstalon’s superiority combined with its lower price position it to become the carbon fiber replacement of choice in the automotive industry.

Copyright 2025 © All Right Reserved Tungstalon